Baopeng Technology, located in Nantong, Jiangsu Province, is a high-tech enterprise integrating R&D, production, and sales. It specializes in the manufacturing of fitness equipment, with core products including CPU/TPU/rubber dumbbells, weight plates, and barbells. The factory boasts advanced production equipment, such as high-precision CNC machining and fully automated polyurethane coating lines, with an annual production capacity exceeding 50,000 tons. Its products are sold to more than 20 countries and regions worldwide. With over 100 patented technologies and a rigorous quality management system (ISO and CE certified), Baopeng is committed to providing customers with high-quality fitness products and professional customized services.

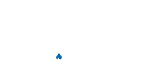

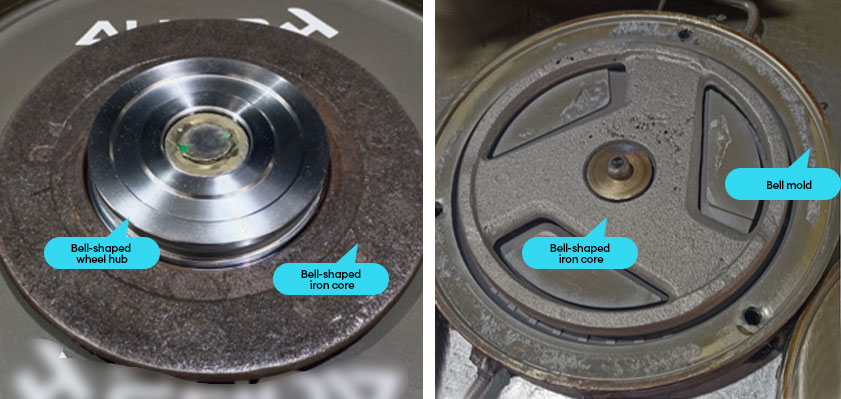

Bell blade structure and cross-section description

Wheel slat structure types:

1. Hub + Iron core placed in mold (CPU)

2. Iron core placed in mold + pressure sleeve (CPU/TPU/rubber)

3. All-rubber sheet (rubber powder, steel shot, and glue mixed in proportion and poured into mold) + pressure sleeve (rubber)

Brief description of wheel hub (bell slat core) production process:

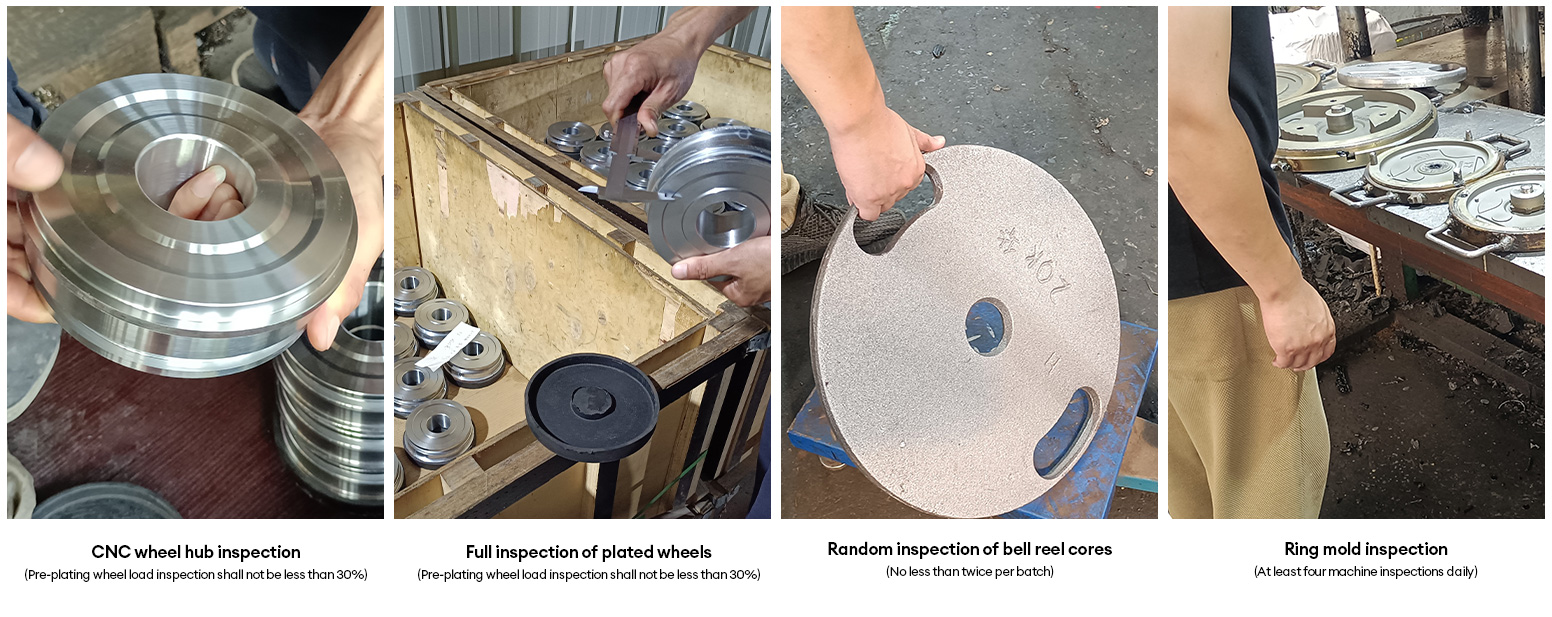

Boll slat wheel hub: sawing → drilling → CNC lathe → electroplating (salt spray inspection) → ready for production

Boll slat core: supplied by the casting plant according to process requirements → random inspection (matching with mold) → ready for production

The process of wrapping iron parts with an adhesive layer:

RUBBER – Rubber (vulcanization process)

TPU – Solid polyurethane material (injection molding process)

CPU – Liquid polyurethane material (casting process)

Other materials (…)

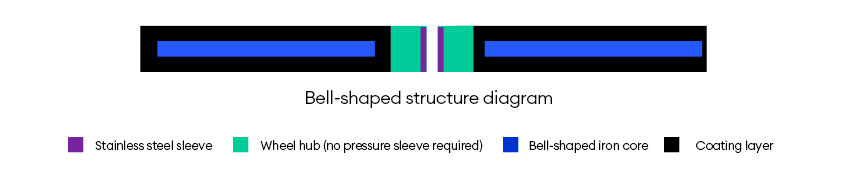

Adhesive Layer Thickness Explanation:

As a professional manufacturer of commercial bells, Baopeng has, through years of production, data optimization, and testing experience, found that bells with an adhesive layer of at least 6mm on one side for CPU bells, at least 6mm on one side for TPU bells, and at least 8mm on one side for rubber bells have a 99.5% probability of passing a violent drop test from a height of 2 meters.

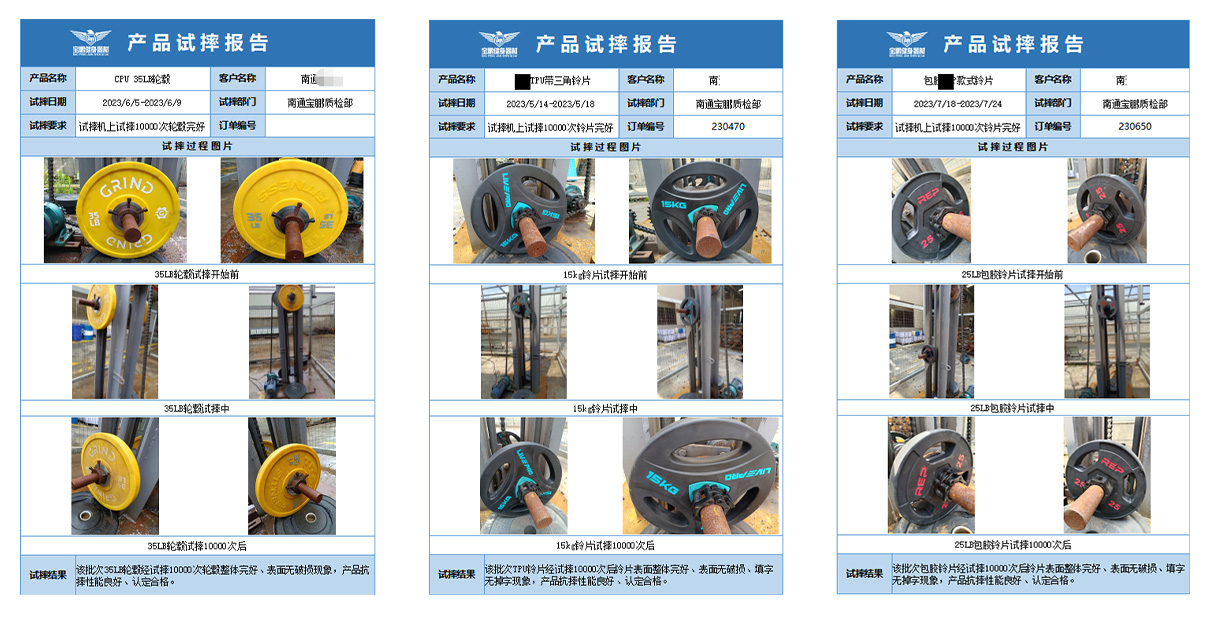

Bell drop test and report:

Baopeng CPU/TPU/Rubber Bell Drop Test Report (Case Study)

Baopeng Quality Control Introduction – Process Sampling and Inspection:

Ring Packaging and Method Instructions:

Baopeng Ring Packaging Method ① – Cardboard Box || Packing Straps (Most Popular Option)

Method 1: After cleaning and quality inspection, the bells are placed in plastic bags, then into cardboard boxes (with tape applied according to customer requirements), and finally secured with two parallel straps using a packing machine before being stacked in wooden crates.

Baopeng Bell Chips Packaging Method ② – Cardboard Box # Packing Straps (Brand Clients)

Method 2: After cleaning and quality inspection, the bells are placed in plastic bags, then into cardboard boxes, sealed with tape, and finally secured with four #-shaped straps using a packing machine before being stacked in wooden crates (small size cross straps).

分割线———————-

Why Choose Baopeng?

At Nantong Baopeng Fitness Equipment Technology Co., Ltd., we combine over 30 years of experience with cutting-edge manufacturing techniques to produce top-tier fitness equipment. Whether you need CPU or TPU dumbbells, weight plates, or other products, our materials meet global safety and environmental standards.

分割线———————-

Want to learn more? Contact us now!

Reach out to our friendly sales team at zhoululu@bpfitness.cn today.

Let’s discuss how we can create high-quality, eco-friendly fitness solutions for you.

Don’t wait—your perfect fitness equipment is just an email away!

Post time: Nov-14-2025