In the current highly competitive market for fitness equipment, product craftsmanship has become the core competitiveness for enterprises. Baopeng’s factory, relying on its exquisite craftsmanship throughout the production process of dumbbells (steel cores), from raw material selection to final assembly, demonstrates a professional level far exceeding that of its peers. It creates high-quality and durable dumbbell products for consumers, setting a new benchmark for industry craftsmanship.

In the processing of the ball head core, the quality control awareness of Baopeng Factory runs through the entire process. After the ball head core is cut, the size of the ball head is first checked to see if it is within the standard range. At the same time, an accurate weight measurement is conducted to ensure it meets the specified weight requirements. This way, probles such as “size deviation and insufficient weight” can be completely avoided from the very beginning.

Weight War: Comparison of Weighing Standards

|

Inspection stage |

BPFITNESS standard |

Industry standard |

|

Initial inspection of core |

4Error ≤ ±0.5% |

±1.5% |

|

Re-inspection after chamfering |

Precise weighing and secondary verification |

Inspection rate ≤ 30% |

|

Final inspection of finished product |

Inspection can be conducted based on customer requirements |

Inspection rate ≤ 20% |

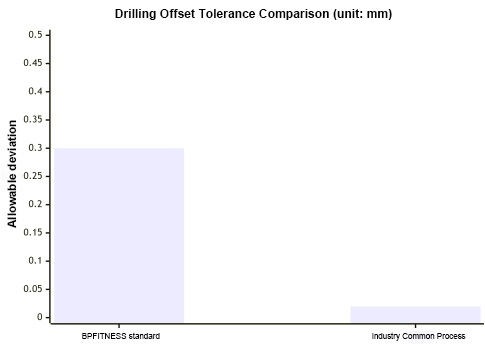

During the drilling process, Baopeng assigned dedicated personnel to check whether the drilling position was deviated, to prevent the deviation of the hole position from affecting the subsequent assembly accuracy; after the chamfering of the ball head core was completed, a weight check was conducted again to ensure the consistency of the weight.

Baopeng Factory: Utilizes CNC numerical control drilling machines (with positioning accuracy ranging from ±0.01mm to ±0.05mm)

Current Industry Situation: 63% of factories use ordinary bench drills and rely on workers’ visual calibration

Before the products are shipped out, Baopeng will conduct drop tests, handle salt spray tests, and inspect the hardness of the adhesive layer. At the same time, it will conduct a final comprehensive inspection on appearance, levelness, size, and weight.

Salt Spray Test: Comparative Experiment on Electroplating Quality

|

Sample type |

24-hour salt spray test |

72-hour salt spray test |

|

Baopeng handle |

No change |

Slight loss of luster |

|

Industry average |

Local rust (≥5%) |

全面锈蚀(≥5%) |

Drop test: Comparison of testing standards

1. Drop height: Baopeng 1.5m vs Industry 0.8m – 1.0m

2. Test frequency: Baopeng 10,000 times vs Industry < 10,000 times

3. Acceptance standard: Baopeng crack in adhesive layer ≤ 2mm vs Industry crack in adhesive layer ≤ 5mm

With a complete and high-standard quality control system throughout the entire process, the dumbbell products of Baopeng Factory have established a reputation in the market as “high quality and high reliability”. In the future, Baopeng will continue to upgrade its quality control technology and adhere to stricter standards to safeguard product quality, leading the quality upgrade in the fitness equipment industry.

Post time: Sep-12-2025