In the fitness equipment industry, weight plates, as crucial gear for strength training, directly impact training effectiveness and safety. Standard plates and competition-grade plates cater to different usage scenarios, adhering to vastly different testing standards. Today, let Bao Peng take us behind the scenes to uncover the mysteries between these two types and explore their key differences!

Precision testing: Competition-level bells have more stringent requirements

Standard plates typically follow industrial-grade standards, allowing a weight tolerance range of ±2%-3%. In contrast, competition-grade plates (such as those certified by the IPF International Powerlifting Federation) must meet a tolerance within ±0.25%. This means a 20kg competition-grade plate cannot exceed 20.05kg or fall below 19.95kg, ensuring fairness in competitions.

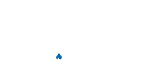

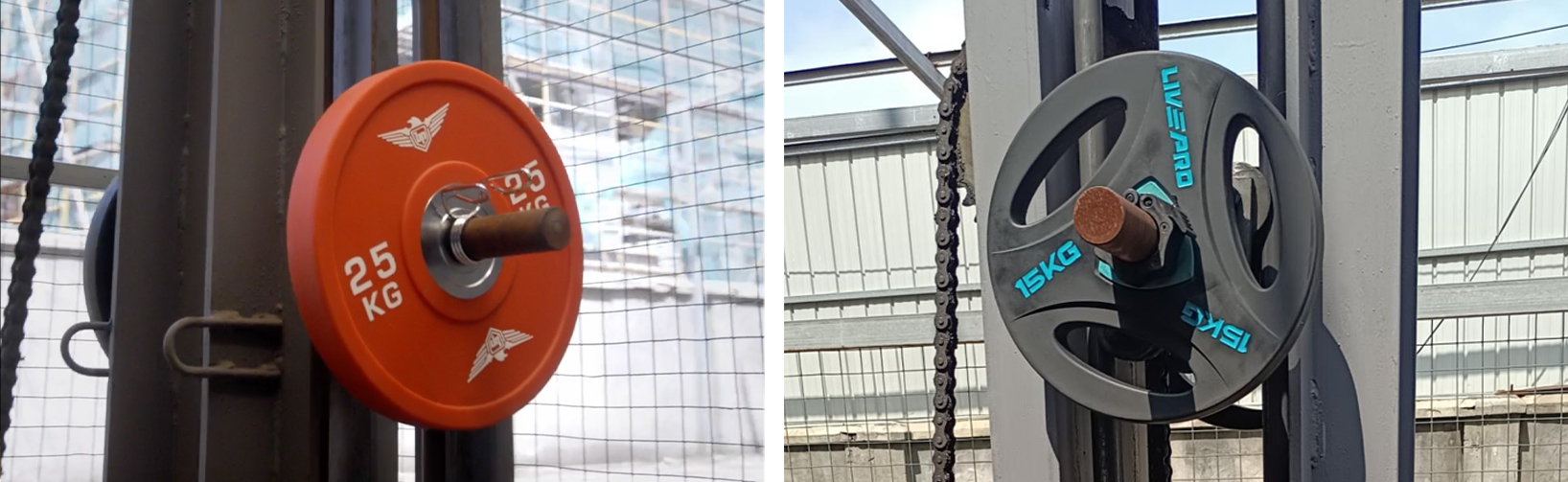

Materials and Drop Testing

Ordinary barbells are mostly made of cast iron + rubber coating, and the focus of testing is on basic impact resistance and rust resistance. Competition-grade cast iron cores usually need to have high fracture resistance, especially under high loads or extreme conditions. In addition to the core finishing, the material also needs to be optimized. We add the element "silicon" to the cast iron core material to enhance the core strength to ensure that the barbell can be used stably in the use scenario to resist impact and maintain stability.

Drop testing is a critical part of quality control. To meet competition scenarios, higher standards are imposed for durability and stability. Standard products undergo 8,000 fixed-height drops, while competition-grade products endure 10,000 fixed-height drops and 100 free-fall drops.

In order to provide users with the ultimate experience and achieve the best product effect and quality standards, we strictly control from raw materials to each production link. We use glue layer materials that are higher than the standards of ordinary CPU commercial products; before pouring the semi-finished core products, we add cleaning, sandblasting, and glue application processes to enhance adhesion and strive for excellence in every detail.

Why Choose Baopeng?

At Nantong Baopeng Fitness Equipment Technology Co., Ltd., we combine over 30 years of experience with cutting-edge manufacturing techniques to produce top-tier fitness equipment. Whether you need CPU or TPU dumbbells, weight plates, or other products, our materials meet global safety and environmental standards.

Want to learn more? Contact us now!

Reach out to our friendly sales team at zhoululu@bpfitness.cn today.

Let’s discuss how we can create high-quality, eco-friendly fitness solutions for you.

Don’t wait—your perfect fitness equipment is just an email away!

Post time: Jun-27-2025