In the market where the homogeneity of fitness equipment products is constantly increasing, a distinct brand logo can make your product stand out among numerous fitness equipment. It is not only a symbol of identity but also a manifestation of professionalism. BaoPeng Fitness is well aware of this, and thus has established a mature dumbbell customization system to ensure that there is no visual difference between the effect drawing and the final product.

First, Identify requirements: understand the product size, color and material. In-depth communication with the customer is the starting point of the customized service. Baopeng Fitness‘s professional team will accurately address the core needs of the customers.

1. Product specifications: precise to the weight in kilograms or pounds.

2. Materials and craftsmanship: whether the main body is made of CPU, TPU, or with rubber coating? Does the handle need a specific density of embossed pattern (such as 1.2mm or 1.5mm mesh pattern) and electroplating color?

3. Style and logo: the presentation method of the brand logo (laser engraving or UV printing or mold making), exclusive colors (providing Pantone color cards for comparison).

After confirming the above information, Baopeng Professional Customers will provide customized proposal prices and produce effect diagrams.

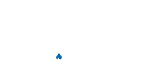

Among them, the customization method of the LOGO often accounts for the largest proportion in communication.

Baopeng Fitness offers three different LOGO customization methods: laser engraving, UV printing, and the LOGO is directly engraved on the mold.

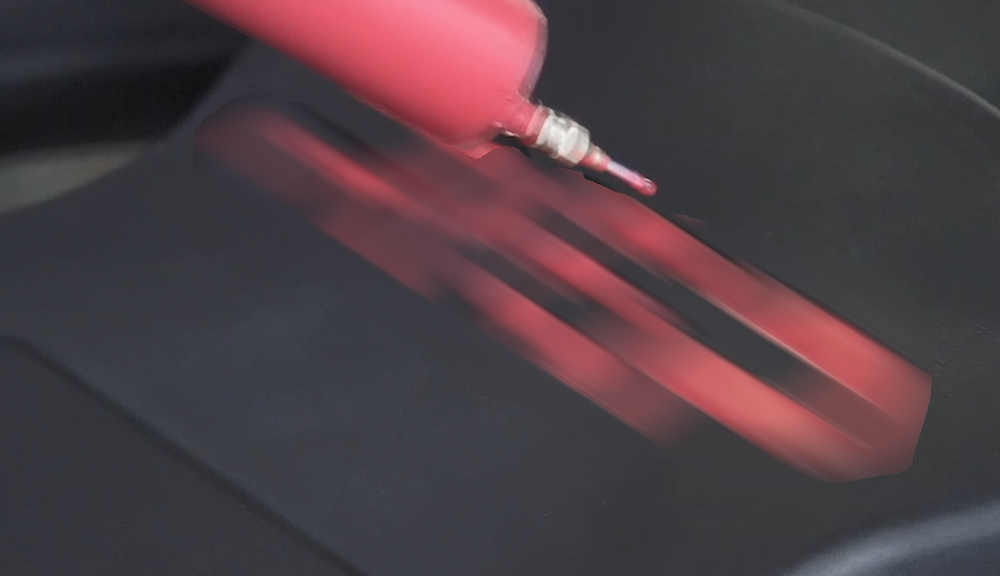

Laser engraving is a physical and permanent marking process. Its principle is to vaporize the surface of the product with a high-energy beam, forming a certain depth of grooves. The advantage of laser engraving lies in its unique durability. The engraved LOGO can still be clearly visible even after long-term wear and use.

On Baopeng’s custom-made dumbbell production line, laser printing is a meticulous and precise process. After completing steps such as ball head vulcanization and handle assembly, the customized parts enter the laser station. Workers, based on the vector graphic files confirmed by the customers, complete the final size and position calibration in the dedicated software. Once the dumbbells are fixed by the precision fixtures, the laser is activated, and the scanning and engraving process is completed within seconds to tens of seconds. Subsequently, the meticulous hand coloring process by skilled technicians follows. Technicians use special color pastes to fill in according to Pantone color numbers and undergo curing treatment to ensure the colors are firmly embedded in the grooves. Although this process takes longer than UV printing, it creates a three-dimensional effect, tactile sensation, and a “embedded” visual effect that no other surface printing technology can match. It bestows upon the product a profound, handcrafted warmth and a sense of luxury and exclusivity.

UV printing is a complex collision of colors. It uses a high-precision nozzle to directly spray special ink onto the surface of the ball head, and then exposes it to ultraviolet light to solidify it. Its advantages are high efficiency and the ability to create complex-colored LOGOs.

Built-in molds: As the name suggests, it means customizing a brand new mold, with the logo being directly produced on the dumbbell ball during the manufacturing process, and formed as one piece.

At Baopeng Fitness, we are not only the providers of solutions, but also the brand promotion consultants. Whether it is the timeless beauty of laser engraving or the brilliant colors of UV printing, the technical team of Baopeng Fitness will ensure that every detail is perfectly presented through rigorous process control. Your brand story deserves to be told precisely using the most suitable techniques.

Post time: Jan-30-2026