The products of BAOPENG FITNESS cover a wide range and possess outstanding professionalism and technical strength. The main products of BAOPENG FITNESS include high-quality PU dumbbells, bell plates and barbells, etc. Among them, the production process of dumbbells is the most complex and the craftsmanship is the most precise. It is meticulously forged in six strict stages and countless minute details.

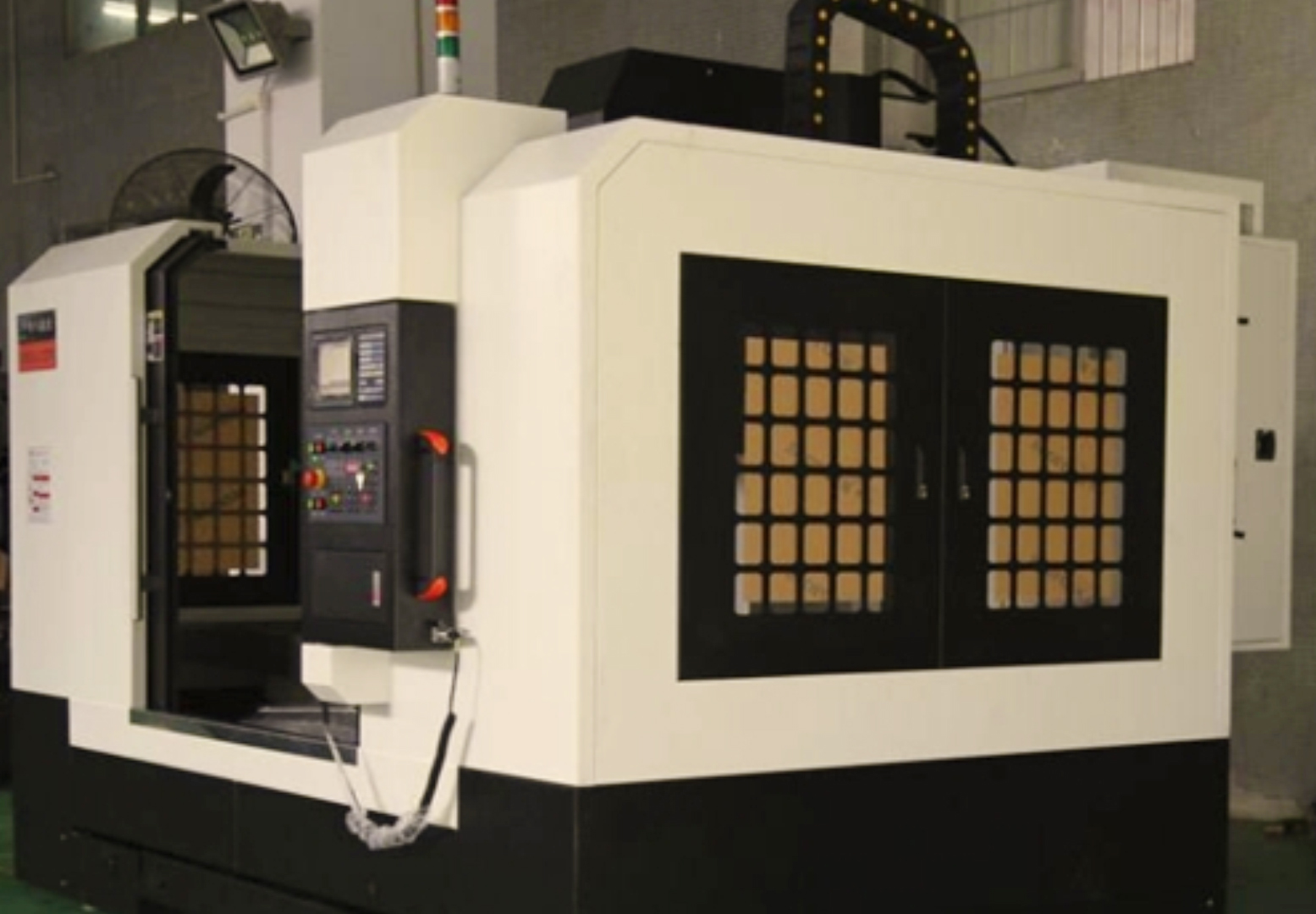

Step 1: Metalworking Manufacturing: Raw Material Cutting

The manufacturing of the ball head is the first step in the production of the dumbbell. Baopeng fitness uses 45# steel and, based on the order specifications, uses a metal band saw machine (B-33, with cooling water and lubricating oil) or a metal circular saw machine (oil-cooled) for precise cutting and material removal. Next, the iron core is positioned on a dedicated machine and then drilled. The standard hole diameter is 29.5 millimeters, and after milling, it is precisely reduced to 30 millimeters. Workers strictly control the drilling accuracy, taking an average of 1-2 minutes per piece, and check one by one to ensure that the hole diameter is not offset. After completion, the inner (R2-3 angle) and outer (R4-5 angle) chamfering of the iron core is carried out. This step significantly improves the anti-drop and wear resistance of the finished product. At the same time, during the production process, it is checked whether the ball heads cut off are within the range and whether they meet the weight requirements.

Step 2: Surface Treatment: Sandblasting Process

The ball heads after drilling need to undergo sandblasting treatment. In a sealed machine, the high-speed jet of iron sand particles will quickly remove the rust and oil stains on the metal surface, creating a rough surface for the ball heads. The purpose is to significantly increase the adhesion and contact area between the iron core and the encapsulated material, fundamentally preventing the cracking or detachment of the adhesive layer during use.

Step 3: Assembly: Close Fit

The handle that has undergone electroplating for rust prevention is closely fitted with the ball head core. The connection between the components is achieved through the interference tolerance calculated precisely, resulting in a tight fit that is seamless and does not require welding, making it as stable as a rock.

Step 4: Vulcanization Process: Material Coating

The semi-finished products after assembly will enter the vulcanization production line. Whether it is the high elasticity and wear-resistant CPU, the delicate touch TPU, or the traditional reliable rubber coating, the raw materials will be precisely adhered to the iron core in a mold with specific temperature and pressure. Eventually, a dumbbell-shaped main body with shock resistance and cushioning properties will be formed.

Step 5: Personalized Customization: Logo Processing

We, according to the customer’s requirements, use technologies such as laser engraving, UV printing, and molds to add the brand logo, weight indication, etc. at the designated position of the dumbbell.

Step 6: Final Quality Inspection before Shipment

For each dumbbell produced by Baopeng fitness, it must undergo strict inspections before being shipped. Besides the basic checks for appearance, size, and weight, it also includes necessary salt spray and drop resistance tests. Only products that meet all quality control standards can be packaged and shipped.

In summary, the production of Baopeng fitness’s dumbbells is a tightly interlinked and meticulous manufacturing process. From the selection of raw materials, precise processing to the final testing, each step has clear standards and quality requirements, which ensures the reliability, durability and professional performance of the products, and meets the needs of every customer.

Post time: Jan-04-2026